Trappist cheese

What is Trappist cheese?

Just like our Trappist beers, our cheeses have Authentic Trappist Product certification. This means they are made within the walls of our Trappist abbey and that monks are always involved in the cheese-making process. The income from our cheeses goes towards supporting the monks, as well as to good causes.

Want to find out more about the “Authentic Trappist Product” label? Then visit the International Trappist Association website.

Three maturation times, three characters

Westmalle Trappist cheese is available in three varieties depending on the maturation period: two, six or twelve months. Each maturation period results in a cheese with its own taste and texture. All of our cheeses are characterised by their low salt content.

Westmalle 2+

This is a creamy, semi-hard Trappist cheese with the aroma of creamy butter and a mild flavour.

Westmalle 6+

This cheese is ripened for six months and has a more pronounced character. Its firm texture and delicious aroma are coupled with a balanced flavour.

Westmalle 12+

Twelve months of patience results in a cheese with intense colour, concentrated aroma and a complex taste. Deliciously spicy, but not salty.

This is how we make our Trappist cheese

In line with the requirements for ‘Trappist’ designation, the cheese-making process takes place entirely within the walls of the Trappist abbey. Everything starts with the cows in the abbey farm.

1/ Milk from our own cows

The milk we use to make our Trappist cheese comes from our own cows. Our cows are milked twice a day, and they are stress-free, because during milking they can eat in peace. As a result, they like to come to the milking carousel of their own accord. Incidentally, they eat the marc that comes from the brewery, sustainably recycling leftovers from the brewing process.

The milk is heated to a limited extent: this is called ‘thermisation’, and ensures safe consumption while retaining plenty of flavour. This is why our milk is not pasteurised: that would be too drastic a process.

2/ From milk to curd

We then pump the milk from the cooling tank into the cheese tub, where we add lactic acid bacteria, which convert the lactose into lactic acid and promote curdling. They also have a beneficial influence on the taste, texture and firmness of the cheese.

Heating the milk to 30°C while stirring, we add rennet. This thickens the milk, after which everything is allowed to rest for half an hour. During this time, nature does its work and the mixture turns into a jelly-like mass: the curd.

3/ From curd to cheese

Now that the curd is firm enough, we cut it into small pieces. We can now separate the whey from the curd more easily. We then wash it with water and stir for a while. The time we take and the way we do this also determines the unique character of our cheeses.

After washing, we press the curd into a solid mass for the first time. This makes it easier for us to cut the curds to size and put them into our rectangular cheese moulds. In these moulds, a hydraulic press machine presses them three more times: once for 15 minutes and twice for 45 minutes. In between, we turn the cheeses over to give them an even shape. Pressing further removes the whey from the cheese and compresses all of the cheese particles into a homogeneous structure.

4/ Brine bath and maturation

Once the cheese blocks have been pressed, they can come out of their moulds and we cut away an edge here and there that was created during pressing. Now they are ready to be bathed. A 12-hour brine bath, more specifically. The salt not only enhances the tangy flavour, but also ensures they can be stored for a longer time.

Finally, in a special ripening room with a temperature between 12° and 15°C, the cheese is given all the time it needs to mature. In addition, we turn it by hand 3 times a week to ensure balanced ripening. The 85-95% humidity in the ripening chamber also prevents the cheese from drying out immediately. Furthermore, the rind is formed and the cheese is given an extra protective layer so that mould does not have a chance to form.

After two months, the first cheese is ready for tasting. But some cheeses keep maturing quietly for as long as six to twelve months. The result: delicious Trappist cheese in 3 different varieties. Each cheese has a light, natural colour as we do not add any preservatives or colouring agents at any stage in the process.

Our own cheese dairy since 1870

The monks have kept cows ever since the monastery was founded in 1794, though in the early days, cheese was still bought from outside. That changed in the mid-19th century when a cowshed was built inside the abbey walls. Our own cheese production began immediately for consumption by the monks and their guests. Outside cheese sales began around 1873.

As a merchant, are you interested in selling our cheeses?

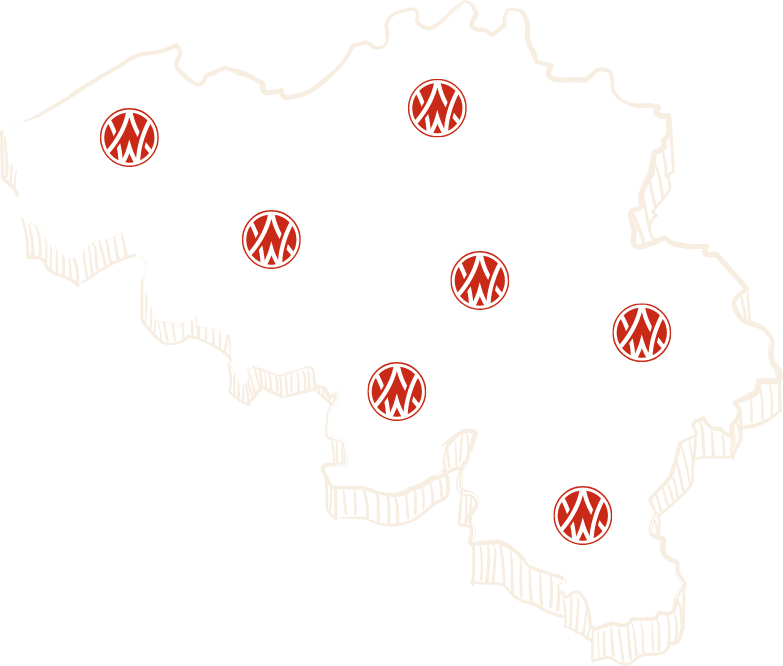

Find our cheeses and our Trappist beer on draught