Trappist beer

What is Trappist beer?

Our Trappist beer carries the international Authentic Trappist Product label.

‘Trappist’ is a protected designation of origin, confirming that we meet three criteria:

- our beers must be brewed within the walls of the Trappist abbey,

- production and business policy are supervised by Trappist monks, and

- the proceeds of the brewery are earmarked for the needs of the monastic community, as well as to reinvest in the brewery, provide support within the Trappist order and to run charitable projects.

Want to know more? Visit the International Trappist Association site or listen to their podcast.

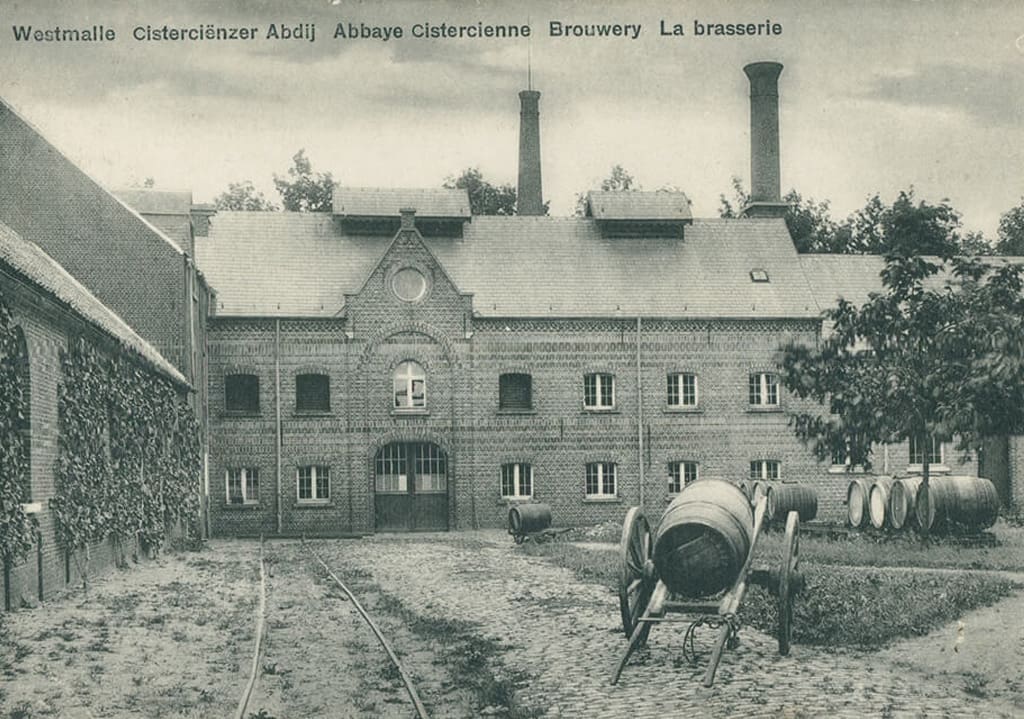

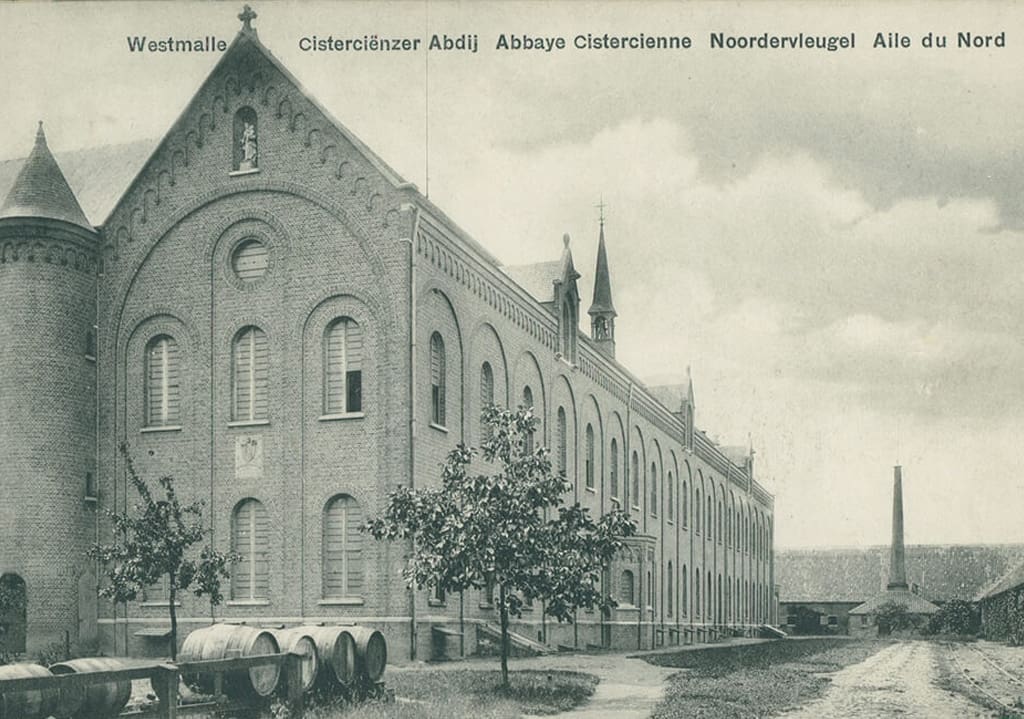

Brewing at the pace of the abbey

At Westmalle, we brew at the same pace as abbey life. The brewing room only begins work when the monks are ready in the morning to say a first prayer together in church. And, despite using modern technologies and techniques, it’s humans who make the final decision in every step of our brewing process.

With respect for tradition and the best ingredients.

We thoroughly monitor our ingredients and our beer at every step of the lengthy brewing process. But despite everything, our beer remains a natural product based on 5 raw materials: selected barley varieties malted according to our specific requirements, a blend of different varieties of hop flowers from renowned European hop regions, pure water from the deep Diestian layer, sugar and the unique home-grown Westmalle yeast.

We do not add stabilisers and do not pasteurise our beers. Yeast is a live medium, so the result can always be slightly different from one brew to the next. This is a nuance inherent to our natural and traditional brewing process – and highly appreciated by the finest connoisseurs.

To brew the best Westmalle every time, we always buy our barley malts and hops from the same malt houses and hop farmers. As a pioneer in Trappist beer, we do not compromise on this. All ingredients are personally and thoroughly checked by our brewmaster.

Everything starts with the barley malt, which we grind into fine flour. In the mash tun, we mix the ground malt with water pumped from 60 metres down in the deep Diestian layer. We heat this mixture with steam: at 73°C, we achieve full saccharification of the malt.

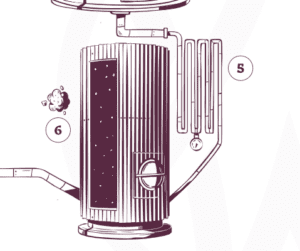

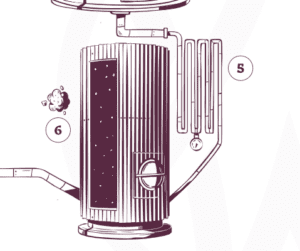

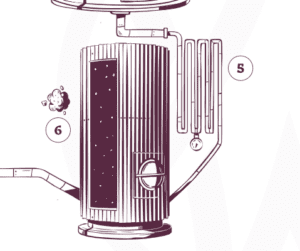

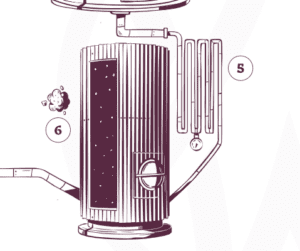

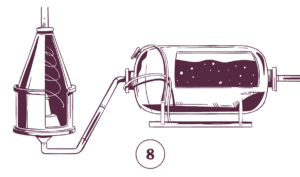

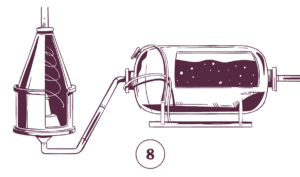

In the filtering tank, the wort (liquid malt extract) separates from the spent grain, which is recycled as fodder for our dairy cows. After filtration, the wort enters the boiling kettle.

At Westmalle we boil the wort for 75 minutes: that way enough water evaporates and there is time to add the six varieties of hop cones at three different points. Before the wort cools, sugar is added and the hop leaves are sieved away: they are used as compost afterwards.

We use the brewing water as a coolant via a heat exchanger. This causes the temperature of the wort to drop to 19 to 20°C and heats up the water for the next brew to 80°C. This is an example of our sustainable approach.

The cooled wort enters the fermentation tanks, where it receives the correct dose of Westmalle yeast to convert the sugars into alcohol and carbon dioxide. This unique yeast gives our beers their typical flavours and aromas. When the yeast wears off, it is collected and prepared to start the next brew.

We then pump the brew into lagering tanks. During lagering, it sits at a lower temperature – specifically 8°C. The yeast residue and proteins sink to the bottom, allowing the beer to clear naturally.

After maturing in the lagering tanks, the beer is filtered in a centrifuge. The brewer adds additional sugar and active yeast to allow secondary fermentation in the bottle. The beer then goes to a collection tank, from where it is filled into bottles. We allow our Westmalle Dubbel, which is intended for barrels, to ferment beforehand. A little bit of yeast goes into the keg so that it keeps better.

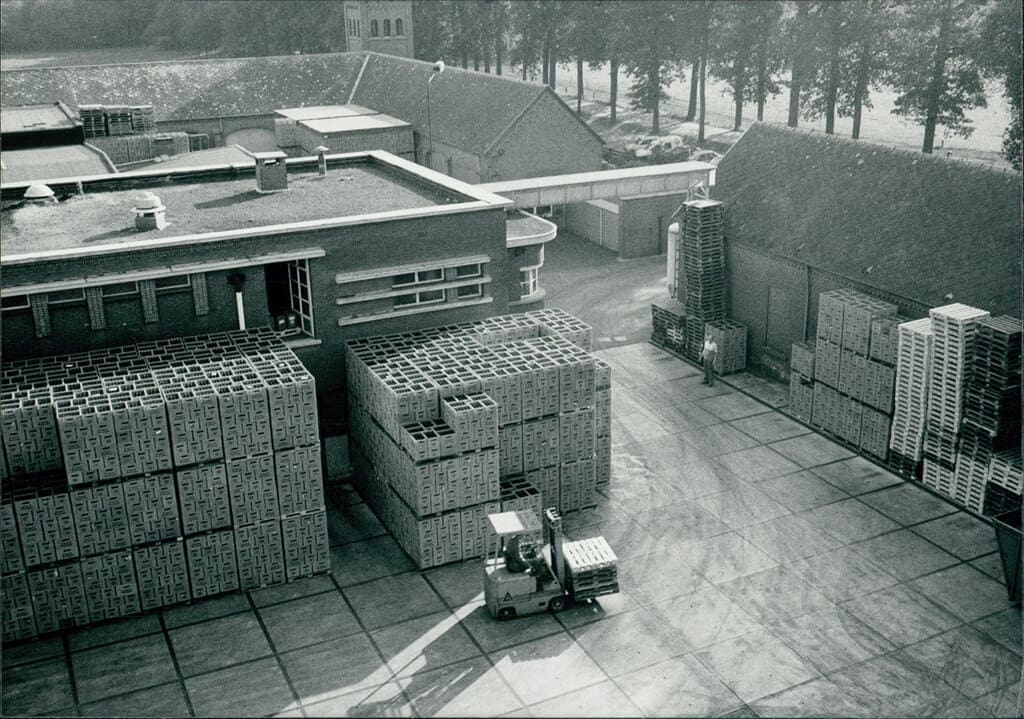

Our bottling plant fills 45,000 bottles per hour. This filling speed ensures that a day’s shift is sufficient to meet our production targets. It also means that our brewery staff can go home on time and no evening or weekend work is necessary, which is an example of our sustainable personnel policy. In addition to bottling, barrels of Westmalle Dubbel are also filled in the plant.

After the beer is bottled, it remains within the abbey walls for another two to three weeks. In our underground maturing warehouse, which stays between 21°C tot 23°C with no temperature fluctuation, the yeast is given time to do its work again. The alcohol content rises a little more and the carbon dioxide formed in the process helps create that delicious head of Westmalle foam.

Looking for original Westmalle gifts?

Choose from a range of original Westmalle products, such as tasting glasses, or check out our corporate promotional gifts.

Find our cheeses and our Trappist beer on draught